Understanding Ammonia Chiller Manufacturers: How to Choose the Best Cooling Solution

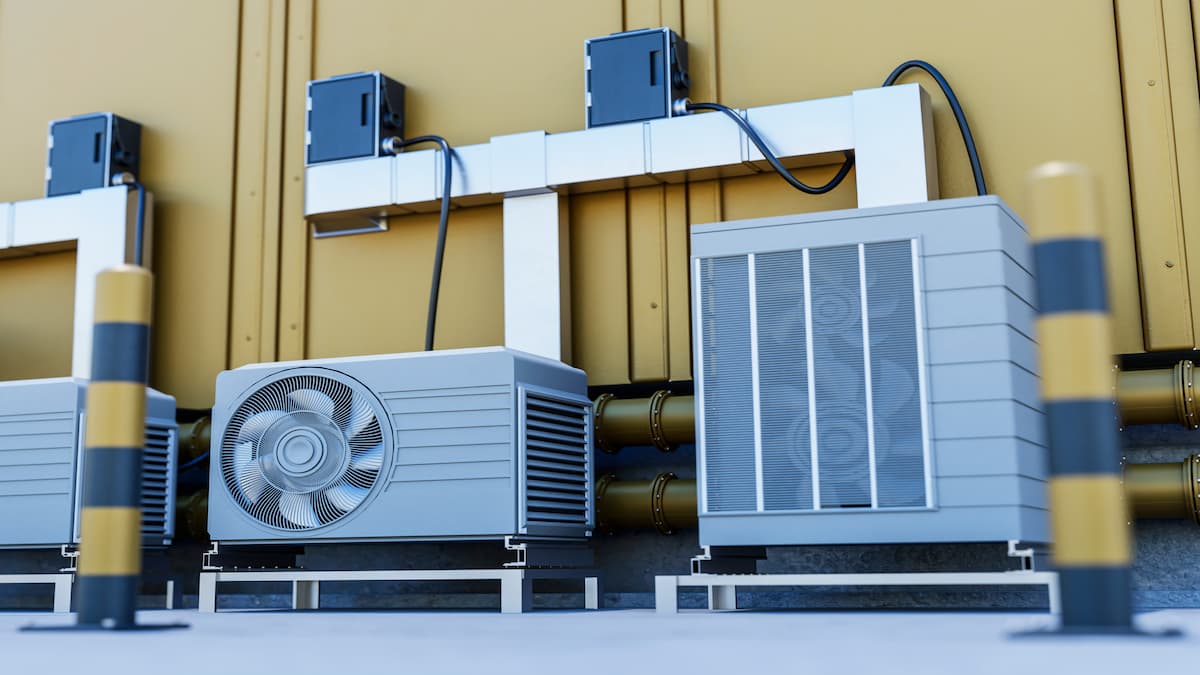

When large-scale cooling is involved, knowing how ammonia chillers work and who manufactures them makes a real difference.

Industrial cooling plays a critical role in maintaining stable operations across many sectors. A reliable cooling system helps control temperature, protect equipment, and support consistent production without interruptions.

For large-scale cooling needs, working with experienced ammonia chiller manufacturers helps industries select systems that are efficient, dependable, and suited for continuous use. The proper manufacturer understands how cooling demands change with different processes and operating conditions.

Modern cooling systems often rely on screw chillers to handle heavy workloads with steady performance. Understanding how these systems work and how to choose the right manufacturer helps businesses make informed decisions with long-term benefits.

What Makes Ammonia Chillers a Preferred Choice

Ammonia-based cooling systems are commonly used in industries requiring strong, consistent temperature control. These systems are designed to support continuous operations without frequent performance issues.

- Ammonia transfers heat very efficiently, helping maintain stable cooling even during heavy use.

- Systems designed by experienced ammonia chiller manufacturers are built to reliably handle large cooling loads.

- These chillers are suitable for facilities that operate for long hours without frequent shutdowns.

- Ammonia-based systems are often chosen for their durability in demanding industrial environments.

- These systems support energy-efficient operations, helping industries manage power consumption effectively.

Because of these advantages, ammonia chillers remain a trusted solution for large-scale cooling needs. Choosing the right system helps industries maintain efficiency and dependable performance over time.

How Screw Compressor Technology Supports Efficient Cooling

Screw compressor technology is widely used in industrial cooling systems because it delivers steady performance under varying load conditions. This makes it suitable for operations that require continuous and reliable cooling.

Handles varying cooling loads smoothly:

Chillers with screw compressors adjust efficiently to changing cooling demands, helping maintain stable temperatures throughout operations.

Supports long operating hours:

These systems are designed to run for extended periods without frequent shutdowns, which is important for round-the-clock industrial processes.

Improves overall system efficiency:

Screw compressor designs help reduce energy wastage by maintaining consistent cooling performance during partial and full loads.

Reduces wear on system components:

Smooth operation helps minimize stress on internal parts, which supports longer equipment life and fewer maintenance issues.

Suitable for large industrial applications:

Many ammonia chiller manufacturers rely on screw compressor technology to meet high-capacity cooling requirements effectively.

These advantages make screw compressor technology a dependable choice for industrial cooling systems. Understanding its role helps businesses select solutions that deliver long-term reliability and efficiency.

Different Types of Screw Chillers You Should Know About

Industrial cooling requirements vary based on space, operating conditions, and resource availability. Understanding the different system options helps businesses choose a setup that fits their specific needs.

Water-based screw systems:

These systems are commonly used in large facilities where continuous cooling and stable performance are required over long operating hours.

Air-based screw systems:

An air-cooled screw chiller is suitable for locations where water availability is limited and simpler installation is preferred.

High-capacity industrial systems:

Many screw chillers are designed to handle heavy cooling loads, making them suitable for demanding industrial environments.

Flexible system configurations:

Different designs allow businesses to choose systems that match their space constraints and operational requirements.

Energy-focused designs:

Modern systems are designed to balance cooling performance with controlled energy consumption to ensure long-term efficiency.

Knowing the differences between these options makes the selection process easier and more effective. The right choice supports stable operations and avoids unnecessary operational challenges.

What to Look for When Choosing Ammonia Chiller Manufacturers

Selecting the right manufacturer plays a major role in the performance and reliability of an ammonia-based cooling system. A well-chosen partner helps ensure the system matches real operating conditions and long-term usage needs.

Proven industry experience:

Established ammonia chiller manufacturers understand industrial cooling challenges and design systems that perform reliably under continuous workloads.

Strong focus on safety standards:

Manufacturers with proper safety practices ensure ammonia systems are designed and installed with controlled risk and reliable operation.

System efficiency and performance balance:

Experienced ammonia chiller manufacturers focus on delivering systems that balance cooling capacity with controlled energy usage.

Ability to offer customized solutions:

Every facility has different requirements, and manufacturers help tailor solutions to achieve better performance outcomes.

Reliable support and service:

Ongoing assistance from ammonia chiller manufacturers ensures smoother operation and timely resolution of performance concerns.

Choosing the right manufacturer helps industries avoid performance gaps and operational issues. A thoughtful selection supports consistent cooling and long-term operational confidence.

Industries That Commonly Use Ammonia-Based Cooling

Ammonia-based cooling systems are widely used in industries that require strong and reliable temperature control. Choosing trusted ammonia chiller manufacturers ensures these systems meet real industrial needs.

- Food and beverage processing

- Cold storage and warehousing

- Chemical manufacturing units

- Pharmaceutical production facilities

- Large industrial plants

- HVAC and large commercial buildings

Because of their reliability and efficiency, ammonia-based systems remain a preferred choice across these sectors. Their ability to handle large cooling loads makes them suitable for demanding industrial environments.

The Key to Smooth Operations

Investing in the right cooling system can significantly improve industrial efficiency and ensure processes run without interruption. Partnering with reliable ammonia chiller manufacturers allows businesses to choose systems that match their operational demands and long-term goals.

Refcon Chillers brings expertise in designing and delivering dependable, efficient solutions. Our focus is on providing equipment that performs consistently, adapts to heavy workloads, and meets the exact requirements of diverse industrial applications.

We view industrial cooling as a cornerstone of efficient operations. By working hand-in-hand with our clients, we deliver systems that maintain stable processes, optimize energy use, and ensure seamless performance throughout daily operations.