Water Cooled Chillers India: Trends and Innovations to Watch

This blog explores how water-cooled chillers in India are evolving with new technologies, smarter designs, and changing industrial demands.

In a country where rising temperatures, energy costs, and production pressures are becoming the norm, cooling efficiency is no longer just a technical detail—it’s a business advantage. Whether it’s pharmaceuticals, plastics, or large-scale manufacturing, businesses are under pressure to manage energy costs, maintain equipment performance, and meet sustainability goals.

This is why water-cooled chillers in India are getting a second look. With better energy performance, quieter operation, and longer lifespan under demanding conditions, they’re fast becoming the go-to choice for large-scale setups.

In this blog, we explore how cooling systems are evolving, the role of smart innovation in industrial chillers, and what’s driving the shift toward more sustainable solutions, especially from leading chiller manufacturers in India.

What is a Water Cooled Chiller?

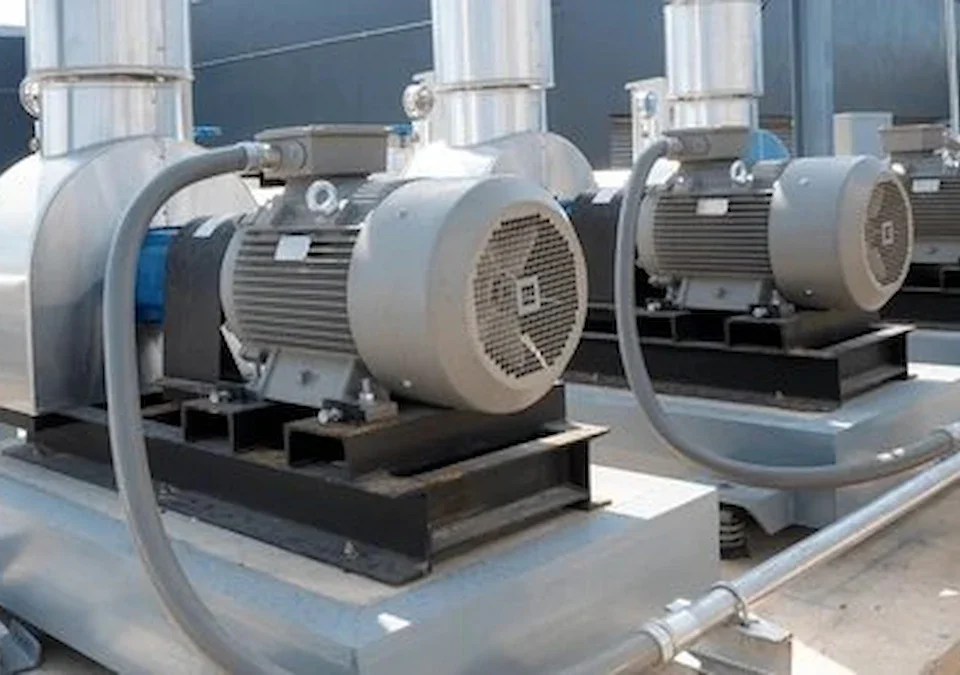

A water-cooled chiller is a type of industrial chiller that uses water as the primary means of heat removal. In other words, it transfers heat from the process or equipment to a water circuit and then the water is cooled utilizing a cooling tower. Water-cooled chillers are ideal for high-capacity applications that require constant temperature control.

Compared to its air-cooled counterpart, it’s generally more efficient—especially in hot climates—though it requires additional infrastructure like cooling towers and water treatment systems.

When comparing the difference between air cooled and water-cooled chillers, certain factors are:

- Efficiency: Water cooled models offer better performance over long periods

- Installation: Air cooled chillers are easier to set up, but may cost more to operate over time

- Space & Noise: Water cooled systems are quieter and take up less outdoor space

For various businesses, particularly those with substantial cooling requirements, industrial water-cooled chillers offer a more practical long-term solution.

Why Water Cooled Chillers Are Gaining Ground in India

Several factors are contributing to the rising demand for water cooled chillers in India:

- Energy Efficiency in Warm Climates: Indian weather, especially in industrial zones, lends itself to water cooled chillers because they have the ability to provide stable performance under high ambient temperature conditions.

- Cost-Effectiveness for Large Operations: These chillers typically offer lower energy costs and maintenance costs when running continuously; hence, a good alternative for high volume and scale manufacturing units.

- Sustainability and Regulations: Stricter norms around emissions and energy usage are pushing companies to upgrade to eco-friendly industrial cooling systems in India.

- Sector Growth: Industries like pharma, food processing, and chemicals are scaling fast—and so is the need for reliable, scalable industrial chillers India can depend on.

Key Trends Shaping the Market

The Indian chiller market is evolving fast. Here are some standout trends defining the shift:

- Smart Automation & IoT Integration: Modern industrial chillers are now equipped with sensors, smart controls, and remote monitoring capabilities. This allows operators to track performance, detect faults early, and optimize energy usage in real time.

- Push for Energy-Efficient and Green Designs: Sustainability has become a big focus, with businesses investing in chillers that are low consumption and low impact. LEED-compliant systems and green refrigerants are becoming more popular.

- Compact and Modular Builds: Space limitations, especially in urban manufacturing zones, have caused demand for chillers with smaller footprints and modular units that are easier to install, maintain, and scale.

- Demand from High-Growth Sectors: Industries like data centers, cold storage, food processing, and pharmaceuticals are driving the demand for high-performance industrial cooling systems in India—and water cooled units are leading that push.

Innovations to Watch

Innovation is at the heart of what’s making water cooled chillers more viable today. Some noteworthy developments include:

- Scroll Compressor Technology: These offer smoother, quieter, and more energy-efficient operation compared to traditional compressors, especially in variable load conditions. Many top water cooled chiller manufacturers in India now provide scroll-based models.

- Hybrid Systems for Optimized Cooling: Combining water and air-based systems, hybrid chillers give users the flexibility to adapt to ambient conditions, improving overall system efficiency.

- Water-Saving Features: With growing water scarcity, newer industrial water cooled chillers come equipped with systems that recycle or optimize water usage without compromising performance.

- Predictive Maintenance Tools: Built-in analytics and smart diagnostics allow operators to catch wear-and-tear before breakdowns happen, reducing downtime and repair costs.

- Eco-Friendly Refrigerants: Transitioning to low-GWP refrigerants is a major step toward cleaner, future-ready chilling systems.

Where Water Cooled Chillers Are Non-Negotiable

Some industries simply can’t afford temperature fluctuations or inefficient cooling. In these sectors, chillers—especially water cooled variants—are mission-critical:

- Pharmaceuticals: Manufacturing and storage of drugs require highly controlled environments. Even small temperature changes can compromise product stability or make batches unsuitable for use.

- Plastics & Injection Molding: In plastic processing, chillers ensure mold temperatures stay consistent, preventing warping, defects, or cycle time delays.

- Food & Beverage: From dairy processing to meat storage and brewing, precise cooling is crucial to prevent spoilage, meet hygiene norms, and extend shelf life.

- Chemical & Petrochemical Units: Many chemical reactions are exothermic and require cooling systems to keep processes stable and safe.

- Data Centers: While not industrial in the traditional sense, these high-performance facilities rely heavily on chillers to prevent equipment overheating and downtime.

Cooling Smarter for an Evolving Industrial India

As industries grow more complex, the way we approach cooling needs to evolve too. Costs related to rising energy bills and new regulations require us to reconsider traditional systems, which will happen across several industries. Water cooled chillers are gaining traction in India, not only because of their efficiency, but also because of their ability to suit local needs. They offer the kind of reliability, performance, and cost balance that large-scale operations can’t afford to overlook.

But it’s not just the technology that’s changing—it’s the people and companies behind it. In India, manufacturers like Refcon Chillers are playing a more involved role than ever before. They’re not just supplying machines: they’re designing smarter systems, building made for Indian conditions, and offering support far beyond the installation. They demonstrate how local expertise can make a genuine difference to industrial infrastructure through developments in advanced scroll chillers and integrated cooling systems.

In the end, whether you’re running a pharmaceutical plant, a plastic molding unit, or a food processing facility, understanding what’s new in industrial chillers isn’t just good planning—it’s smart business.