Brine Chiller Systems: Features & Applications for Efficient Industrial Cooling

Maintaining the perfect temperature is crucial for many industrial jobs. If things get too hot, it can mess up equipment, make products not as good, and slow down production. Regular cooling methods can be a pain, not very effective, and expensive. But using brine chillers is a reliable, efficient, and smart way to keep things cool in industries.

What are Brine Chiller Systems?

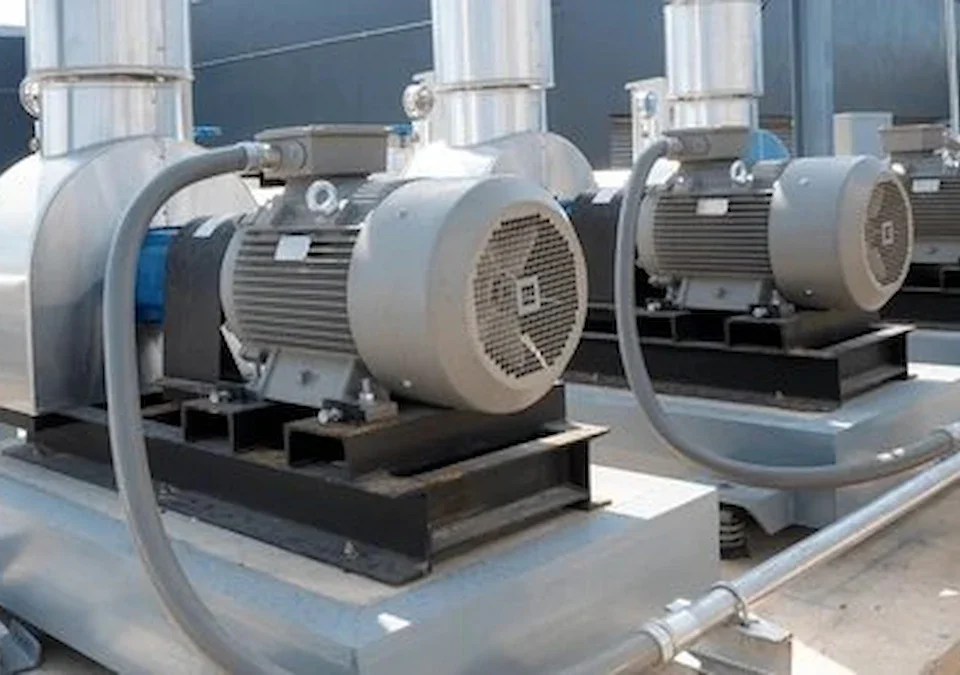

A brine chiller system is a type of industrial chiller that uses a brine solution (saltwater) as a coolant. Brine offers several advantages over water alone. It has a lower freezing point, allowing for colder process temperatures. Also, brine solutions can be formulated to prevent corrosion within the system.

Brine chiller system components work together for temperature control. Here are the components listed below:

- Compressor: This heavy-duty pump increases the pressure and temperature of the refrigerant. By compressing the refrigerant gas, the compressor creates a high-pressure, high-temperature state.

- Evaporator: Heat from the brine solution is absorbed by the refrigerant here. The evaporator is a heat exchanger with a large surface area. It allows efficient heat transfer. As the refrigerant absorbs heat, it evaporates from a liquid into a gas.

- Condenser: Heat from the refrigerant gas is released to the surrounding environment in this unit. The condenser is another heat exchanger, typically cooled by air or water. As the gas turns into a liquid, it releases the absorbed heat.

- Expansion valve: Here, the pressure and temperature of the refrigerant gets lower before it goes back into the evaporator. This is common in commercial chillers used for businesses. The expansion valve controls how much refrigerant goes into the evaporator. Thus, lowering the valve pressure helps refrigerant absorb heat in the evaporator.

- Brine pump: This pump moves the brine solution around, taking heat away from the part that needs to be cooled. The chilled brine solution is then pumped back to the process or equipment to absorb more heat.

Features of Efficient Brine Chiller Systems:

Key features of brine chiller systems that make them work efficiently:

- Durable Construction: Strong materials like stainless steel don’t rust easily. They ensure the system lasts long and doesn’t leak or break down immediately.

- Advanced Control Systems: Microprocessor-based control systems provide precise temperature control and efficient operation. These systems allow for automated operation and real-time monitoring of system performance.

- Energy-Saving Features: Strong materials like stainless steel don’t rust quickly. They make sure the system lasts long and doesn’t leak or break down easily. Also, optimized heat exchangers maximize heat transfer efficiency, further minimizing energy use.

- Corrosion-Resistant Materials: Using materials that don’t rust or wear out in the system helps parts last longer. It means less fixing and makes the system work for a longer time.

Benefits of Brine Chiller Systems:

There are numerous benefits of brine chiller systems across industries. These systems are indispensable for efficient cooling needs. They maintain product quality and reduce energy costs. Here are some of the benefits below:

- There are numerous benefits of brine chiller systems across industries. These systems are indispensable for efficient cooling needs. They maintain product quality and reduce energy costs. Here are some of the benefits below:

- Energy Efficiency: Energy costs are a significant concern for many industrial operations. Brine chiller systems can be highly energy efficient. This is observed when incorporating features like variable-speed drives and optimized heat exchangers. Hence, contributes to increased chiller efficiency. Thus, manufacturers prioritize energy efficiency in their chiller designs. High-quality materials and efficient components minimize energy consumption, leading to lower operating costs.

- Reduced Maintenance Costs: Brine chiller systems require less maintenance than other cooling methods. The durable construction of Refcon’s chillers minimizes downtime and maintenance costs. High-quality materials resist corrosion and wear. This extends the lifespan of the system and reduces the need for frequent repairs.

Applications of Brine Chiller Systems:

Brine chiller systems are a versatile cooling solution across various industries. Here are some key applications of brine chiller systems:

- Food and Beverage Industry: Brine chillers keep food fresh in stores and food factories by making sure the fridges and coolers stay cold. They also cool down beverages in soda fountains, ensuring your drinks stay refreshing.

- Chemical Processing: A brine chiller is an essential component in chemical industries. They cool down reactions and keep temperatures steady in different processes. From pharmaceuticals to plastics, brine chillers help ensure product quality and safety.

- Pharmaceuticals: Imagine life-saving medicines. These medications often need to be stored at specific, very cold temperatures to stay effective. Brine chillers ensure these medicines stay perfectly chilled, safeguarding their quality and potency.

- Dairy: From creamy cheese to refreshing yogurt, the dairy industry relies on precise temperature control to ensure product safety and taste. Brine chillers keep milk cool during processing and storage. Preventing spoilage and maintaining that delicious dairy goodness.

- Plating: Ever wonder how shiny silverware gets its gleam? The process of electroplating, which creates that shiny finish, involves keeping things cool. Brine chillers play an important role in regulating the temperature of the electroplating bath. Ensuring a flawless and metallic finish.

- Data Centers: Brine chillers are crucial for keeping servers and other electronic gear cool in data centers. By maintaining optimal temperatures, these chillers prevent overheating. Thus, ensuring the smooth functioning of critical IT infrastructure.

- Medical Imaging: In medical departments, brine chillers cool down MRI machines and other imaging gear. This ensures accurate imaging results while preventing equipment damage due to overheating.

Brine chiller systems are used in lots of industries and daily life. They keep food fresh and make sure equipment in data centers and hospitals runs smoothly. These chillers are critical for making sure everything runs properly in different areas.

Brine chiller systems offer a compelling solution for industrial cooling needs. Plus, needing less maintenance helps cut costs and makes industrial refrigeration more efficient.

When selecting a brine chiller system, Refcon Chillers based in Mumbai, India, stands out as a trusted partner. Our commitment to quality is evident in the use of high-grade materials throughout our chiller designs. Our advanced control systems make sure the temperature is just right. They also save energy and money, which is good for the environment and your wallet.

We have many different brine chillers to choose from. They come in different sizes and setups to match what your industrial operation needs. Our experts can help you pick the best cooling option. It’ll save money and make your process work better. Contact Refcon now to talk about what you need and see how a brine chiller can improve your cooling setup.